SYNCHRONIZE PANEL

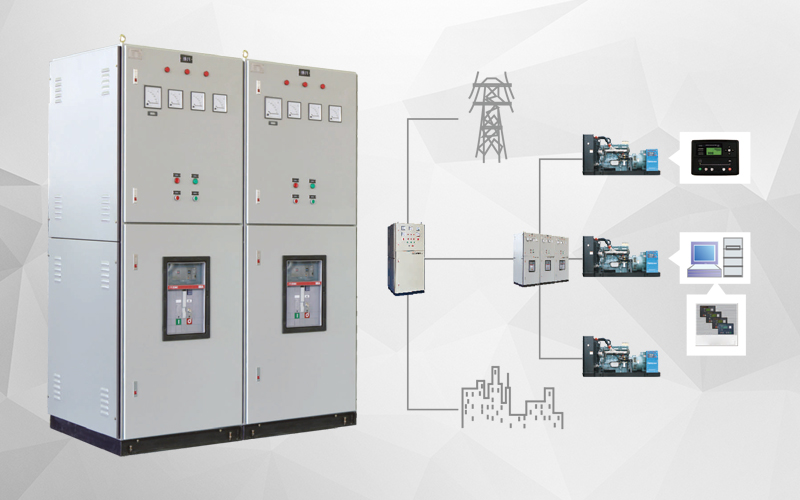

Synchronize Panel

Specification

Variety of Synchronizing and Auto Load Sharing Control Panels.

Synchronization and Automatic Load Sharing between multiple Power sources/lines like Mains, Grid, Generators.

Microprocessor based Controller with a high degree of customization, which can be configured to meet the Clients requirements.

Synchronizing Panel Construction Details

- Modular / Non- compartmentalized construction.

- Panel structure with MS CRCA/SS.

- Indoor / Outdoor type Structure.

- Single front/double front Operated.

- Provision for Extensible for future use.

- Provision of Rubber Gaskets to meet IP requirement like IP-42/52/54/55/65.

- Arrangement for heat dissipation by means of Exhaust Fan or Lowers.

Synchronizing and Auto Load Sharing Panel Pre Treatment And Painting

- Three Tank / Seven Tank Pre treatment process

- Final paint shade as per IS or client specifications

- Synthetic Enamel / Epoxy based primer / Powder coating as per customer’s requirement

Synchronizing and Auto Load Sharing Panel Bus Bar Arrangement & Cable Alley

- Electrical Grade Aluminum / Copper Busbar

- Main busbar chamber at top / bottom of the Panel

- Separate chamber for vertical dropper

- Busbar System design on basis of continuous Current rating and Fault level with stand capacity

- Allowable temperature rise as per IS 8623 or as per specifications

- Busbar supports of SMC/DMC Material

- Top / Bottom cable entry. Detachable gland plate for cable entry

Synchronizing and Auto Load Sharing Panel Assembly & Wiring

- Selection of components from Approved / Reputed vendor list as per Approved Drawing

- Design of Internal Layout fo optimum usage of space

- Internal wiring with 660/1100 v Grade PVC coated stranded Copper Flexible Wires

- Crimping Lugs are used for intrnal Connections / Terminations

Synchronizing and Auto Load Sharing Panel Quality Assurance & Control Systems

- Inspection of Fabrication structure for dimension as per approved G.A. drawing

- Inspection of Painting / Powder coating